-40%

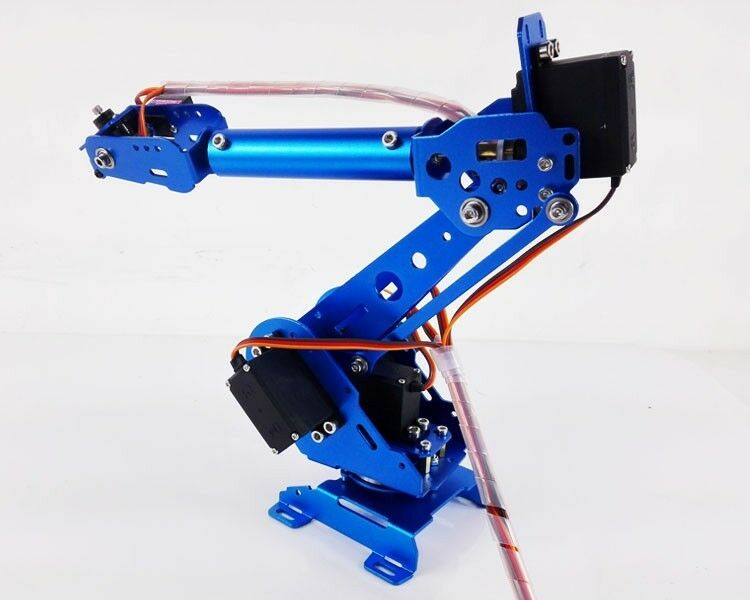

6 AXIS 2006 KUKA MODEL KR 240-2 2000 HIGH PAYLOAD CNC ROBOT ON HEAVY BASE

$ 10296

- Description

- Size Guide

Description

PLEASE CALL JIM FOR MORE INFO 7146121480TNT INDUSTRIAL ORANGE CALIF

Robot Specifications

Axes:

6

Payload:

240.00kg

H-Reach:

2700.00mm

Repeatability:

±0.1200mm

Robot Mass:

1267.00kg

Structure:

Articulated

Mounting:

Floor

Robot Motion Speed

J1

86 °/s (1.5 rad/s)

J2

80 °/s (1.4 rad/s)

J3

79 °/s (1.38 rad/s)

J4

100 °/s (1.75 rad/s)

J5

110 °/s (1.92 rad/s)

J6

184 °/s (3.21 rad/s)

Robot Motion Range

Series 2000: Multi-talents with a modular design. Extremely powerful motors, gear units and servo drives – Series 2000 robots give you greater performance. These talented all-rounders come in five rating classes: for payloads from 150 to 270 kg and reaches from 2,700 to 3,000 mm. Thanks to their modular design and the wide range of expansion options, these robots can be quickly upgraded or converted – and thus perfectly adapted to your application. As if that were not enough, Series 2000 robots are also available as special variants: Cleanroom (CR) for stringent cleanroom requirements; Foundry (F) for environments with a high degree of fouling and high temperatures; and an optional variant with food-compatible H1 oil. The advantages: a high degree of planning reliability and security of investment. Dimensions: mm »TECHNICAL DETAILS KR 240-2 1) Relative to intersection of axes 4/5 »Extremely modular – extremely expandable The 2000 Series offers a wide variety of models, as well as numerous expansion options such as different arm extensions or mounting variants for the ceiling or floor. In this way, the robots can also be quickly retrofitted for increased payload or reach. There’s no more laborious, cost-intensive implementation of new systems – and production can start in record time. The advantages: flexible production and rapid commissioning. »Extremely powerful – extremely precise High speed and maximum output: the high installed motor capacity and high-torque gear units in all axes make the 2000 Series highly dynamic and extremely powerful. Added to this is the precision control, which gives these high-performers a repeatability of ±0.06 mm. The result: better manufacturing quality, fewer rejects, and thus greater efficiency for your production. The advantages: shorter cycle times and higher quality.