-40%

2005 KUKA KR16 Robot Milling Cell - COMPLETE SYSTEM w/ KRC2 Controller

$ 14520

- Description

- Size Guide

Description

2005 KUKA KR16 Robot Milling CellCOMPLETE SYSTEM w/ KRC2 Controller

This KUKA KR16 robot with KRC2 ED05 Controller is in excellent working order and excellent shape with only very minor scratches. The robot is mounted to a custom cnc milling cell with a tri-leg design with designated areas for three milling tables. The milling table is height adjustable with precision cut plug holes for fixturing stock material. The robot has a 2.2Kw, water-cooled spindle motor with a built-in ER16 collet connection as an end effector. The KRC2 controller and teach pendant are in excellent shape and working order.

The complete system is

EXTREME LOW HOURS

at a total of

ONLY 82.77 HOURS

of total robot runtime!!!

SEE VIDEO OF SYSTEM UNDER POWER:

Robot moving: https://youtu.be/Kh8elSiKuLc

System walk around:

https://youtu.be/wP9SgemZXEw

CONDITION:

Used - Extremely excellent condition

Fully tested and operational

Very minor scratches and rubbed areas from previous transport.

INCLUDES:

KR16 Robot

KRC2 ed05 Controller

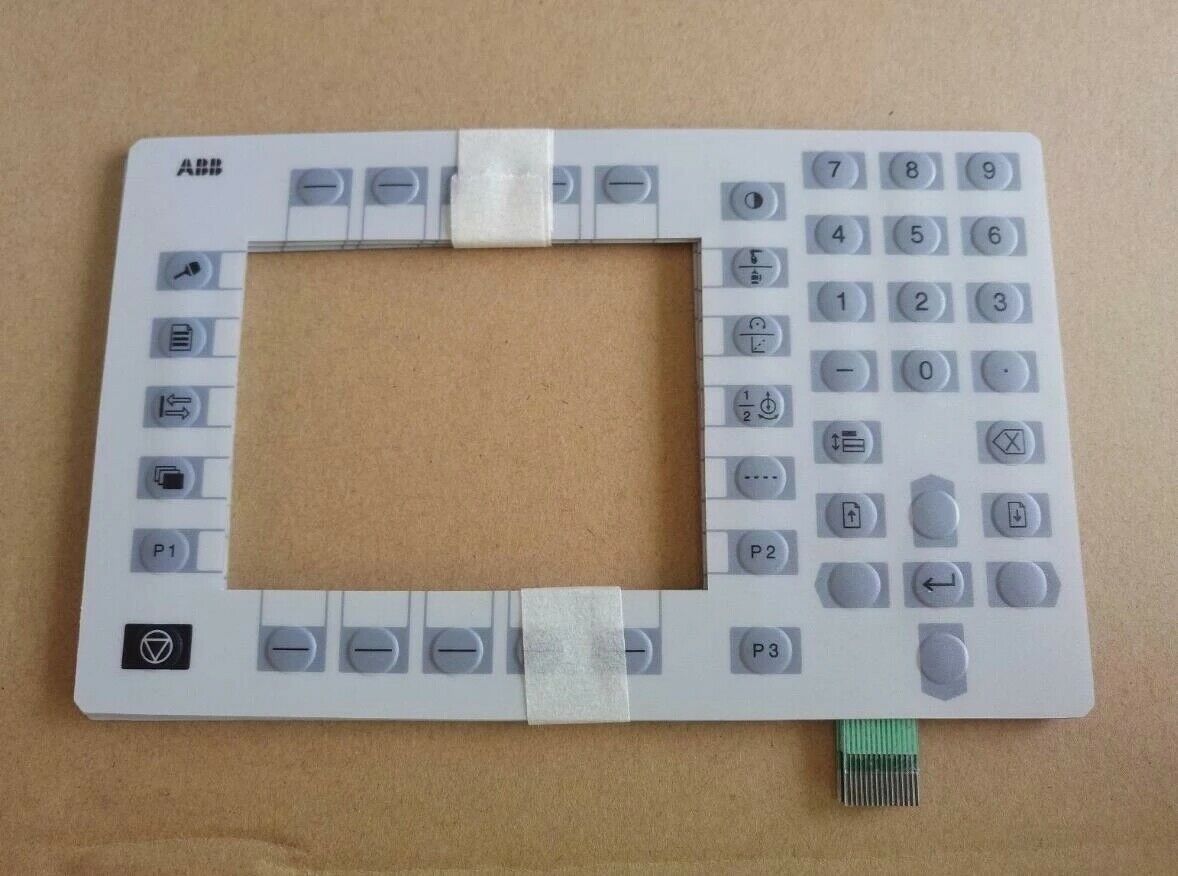

Teach Pendant

Cables

All KUKA Manuals w/ all software and digital manuals

Tri-leg Robot Stand w/ fixture table

2.2kw 24,000 rpm Spindle - Water-cooled

Variable motor controller for spindle

***Phase Converter and Transformer from single phase 220V to 3 phase 480V available upon request***

SPECIFICATIONS:

ROBOT: KUKA KR16

CONTROLLER: KRC2 ED05

CONDITION: Excellent - Near Brand New

YEAR: 2005

MAX PAYLOAD: 16 kg

MAX REACH: 1611 mm

CONTROL SOFTWARE: KRC Software V5.2.12 HF1

ROBOT HOURS:

82.77

Total Hours

ROBOT WEIGHT: 235 kg (dry weight)

CONTROLLER WEIGHT: 314 kg

VOLTAGE: 480V 3 Phase

RATED CURRENT: 8 amps

MAIN FUSE: 20 amps

SPINDLE RPM: 24,000 RPM max

SPINDLE TORQUE: 2.2 Kw

SPINDLE COOLING: water-cooled

TOOL INTERFACE: ER20 Collet (Built-in)

SHIPPING:

Contact us for shipping quote or questions about shipping that you may have.

No additional loading charges will be added.

Sparc Industries (seller) has used this system in the past to machine parts out of softer materials such as wood, tooling foam and fiberglass. We have consistently taken great care of our equipment since its working order and condition is ultimately how we are able to produce parts and keep business operations going. We have tried our very best to show and describe the accurate condition and features of this robotic milling system without any misrepresentation. The reason for this sell is due to not needing the robotic capabilities any longer with changing business direction and needs. If you have any specific questions or concerns, please contact us and we will be happy to answer any questions in detail.